Category

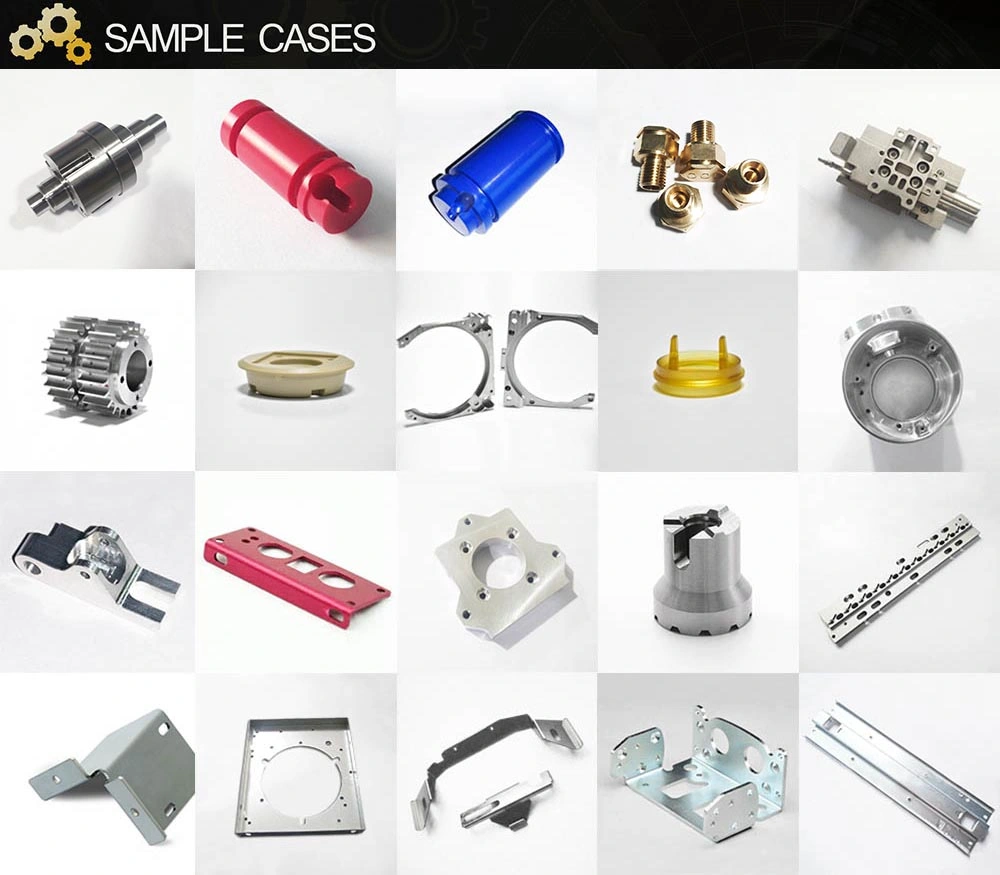

OEM Titanium Alloy Zinc Alloy/Aluminum Alloy CNC Milling Turning Machining Mechanical Parts

OEM Titanium Alloy Zinc Alloy/Aluminum Alloy CNC milling turning Machining Mechanical Parts Feature of CNC parts 1. Prec

Basic Info

| Model NO. | Titanium cnc machining |

| Warranty | 24 Months |

| Customized | Customized |

| Advantage | Use Widely |

| Condition | New |

| Application | Auto and Motorcycle Accessory, Hardware Tool, |

| Surface Treatment | Anodizing |

| Production Type | Single Production |

| Machining Method | CNC Machining |

| Material | Nylon, Steel, Copper, Aluminum, Iron, Titanium |

| Standard | Unstandard |

| Transport Package | Polybag Anti-Shock Foam Into Carton Box |

| Specification | As per Drawing |

| Trademark | OEM |

| Origin | Shenzhen, China |

| HS Code | 8108909000 |

| Production Capacity | 1000PCS/Day |

Product Description

OEM Titanium Alloy Zinc Alloy/Aluminum Alloy CNC milling turning Machining Mechanical PartsFeature of CNC parts

1. Precision Cnc stainless steel parts strictly according to customer's drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.Our freight price is often 30-50% lower than customer's

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015 and ISO13485:2016

Material Available for CNC Machining

| Material | Stainless steel | SS201 SS303 SS304 SS316 17-4PH SUS440C |

| Steel | Q235 20#-45# etc | |

| Brass | C36000(C26800) C37700(HPb59) C38500(HP6 58) C27200(CuzN37)etc | |

| Iron | 1213 12L14 1215 etc | |

| Bronze | C51000 C52100 C5400etc | |

| Aluminum | Al6061 Al6063 Al7075 AL5052 etc | |

| Alloy | A2 D2 SKD11 DF2 XW/5 ASP-23 |

| Our Processing | CNC machining, CNC milling and turning, drilling, grinding, , stamping, tapping, |

| Surface finish | Hard Coating Black Anodize Clear Anodize Hard Chrome ,Clear Zinc Plasma Niride |

| Tolerance | 0.005mm |

| QC System | 100% inspection before shipment |

| Drawing format | DWG/ IGS/ STEP/STEP,/IGES/X-T/PDF and etc. |

| Packaging | Standard package / Carton box or Pallet / As per customized specifications |

| Payment Terms | 1) Western Union for samples cost or very small order 2) 100% T/T in advance when amount less than 1000USD 3) 50% deposit, 50% balance by T/T before shipment when order amount from 3000USD to 5000USD. 4) 30% deposit, 70% balance by T/T before shipment when order amount over 5000USD. 5) L/C payment term for big amount order is acceptable. |

| Trade terms | EXW, FOB, CIF, As per customer's request |

| Shipment Terms | 1) 0-100kg: express & air freight priority 2) >100kg: sea freight priority 3) As per customized specifications |

| Note | All CNC machining parts are custom made according to customer's drawings or samples, no stock.If you have any CNC machining parts to be made, please feel free to send your kind drawings/samples to us anytime by email. |

KGL Machinery&Electronics(KGL) was founded in 2013, an independent private enterprise that integrated R&D, production, sales and service.KGL is focused on CNC precision machining parts, mainly applied in the field of robotics, communications, medical, automation, and custom-designed complex parts and custom-designed equipment.The core competitiveness is rapid response capability, quality assurance system and cost control ability.We provide value-added services to customers through more technical supporting, high quality product and rapid response business processing.So customers will be more focused on their own business and thus enhance customer value.KGL Machinery&ElectronicsNow has high precision 3 axis CNC vertical machining center, 4 axis machining center, 5 axis machining center imported from Taiwan, precision grinding machine, precision wire-cut, EDM and CNC lathe about 50 units.The Max machining range is 2100*1600*800mm, and the machining accuracy can be achieved to 0.005mm.The inspection instrument has CMM, profile projector, digital micro dial, high gauge, ID &OD micrometer, and so on.Professional and experienced management, engineers, inspectors and production staff is about 80.The main processing materials include cast iron, extruded material, steel, aluminum alloy, copper, stainless steel and various engineering plastics.Our company is aiming at "professional quality and excellence service".We have passed ISO9001:2015 and ISO13485:2016 quality management system certification.The company has always been oriented by customer demand and respect for talents, constantly improve their strength, improve service level and quality.With many European and American, Asian and domestic customers, we have established long-term good relationship with common progress.Sincerely expect to join hands with you to create the future.

ISO13485:2003 ISO9001:2008

Q1:Are you a manufacturer?A1:Yes, we are a medium size ISO13485/ISO9001 certificated manufacturer with a wide range of advanced equipment.Warmly welcome to visit our factory so that you can make sure this point.Q2:What is the MOQ?A2:Minimum Order Quantity is one piece/set.If you require more qty,the price can be more competitive.

Q3:Can you do the mass production?A3:Yes,we are a factory which can provide service of precision CNC machining, rapid prototyping, wire cutting, tooling building and etc.After you confirm the samples, we can start mass production.It is very convienient for customers toChoose us as a one-stop solution supplier.Q4:Which 3D drawing files should go with the machines?A4:CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, for *STL format,it goes with 3D printer and SLA.Q5:Is it possible to know how are my products going on without visiting your company?A5:We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.Q6:Will my drawings be safe after sending to you?A6:Yes, we will keep them well and not release to third party without your permission.Q7:What shall we do if we do not have drawings?A7:Please send your sample to our factory,then we can copy or provide you better solutions.Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Thank you very much for reading, and warmly welcome to inquiry or visit us.If any question please feel free to contact.